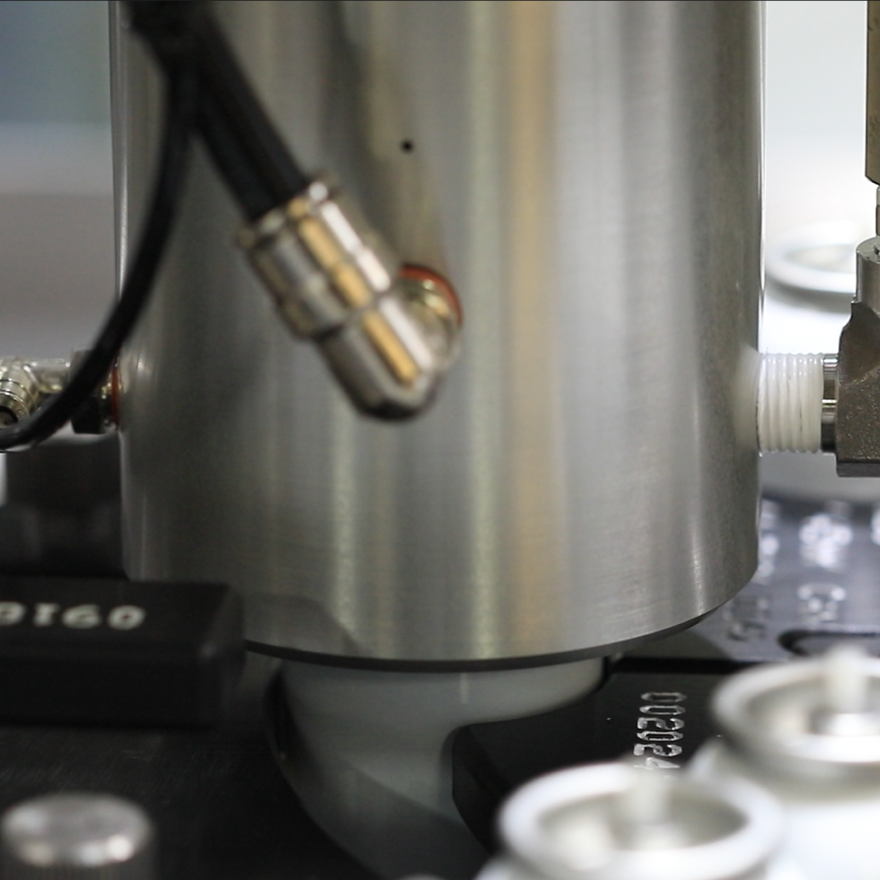

BOV gassing

Bag-On-Valve gassing refers to the step in the process where the can is filled with low pressure compressed air in the space between the can and the flexible bag after which the valve (attached to the bag) is crimped to contain the gas in the can. The term used in this context is Under-The-Cup as the gas is passing the space under the valve edges before it is tightly attached to the can.

Pros and cons

BOV packaging is simpler than traditional aerosol cans. Due to the bag, the content is not in contact with the propellant which is useful when filling product that is sensitive to certain gasses or that may react with the propellant such as food products, pharmaceuticals, and cosmetics.

The only limitation on using a BOV package would be with a product that requires a hydrocarbon to dissolve solids or thin the product to spray. The additional cost for the bag may be another topic to take into account when considering BOV packaging.

ContactThe equipment

Bag-On-Valve experience is available with our partners. They have over a decade long history with this technology. Since their founding, they have recognized the advantages of this system, and have implemented it into dozens of designs for clients, spanning a wide array of products and uses. BOV machinery is thier strongest seller, year after year, thanks to:

- its affordable start-up costs

- easy-to-learn operation

- cleaner untainted end-product

BOV machinery is our strongest seller, year after year. . .

Jim McBride

MBC Aerosol

Download whitepaper

What is the difference between conventional aerosol and bag on valve?