Gassing shaking

Gassing shaking is a time-over-pressure technology where propellant gas is added to the can while simultaneously shaking the can with a frequency of up to 550 rpm. Typical propellants used are CO2 and N2O.

Shaking is mainly used in the whipped cream market in combination with N2O as the propellant. Other segments and applications are gaining momentum as the benefits are being recognized by manufacturers and fillers in applications like cooking sprays but also personal care and industrial products.

Advantages

As a result of the shaking, the gas is mixed with the content and more gas can be added compared to regular time-over-pressure techniques. This makes it possible to significantly increase the content of the can up to 80-90% lowering packaging and logistics costs. It also opens opportunities to replace LPG-based propellants and even BOV systems, again resulting in cost savings and simplification of production processes. The process has specific advantages in combination with lower viscosity products like creams or oil where a critical parameter is the “interaction” between the product and the propellant.

download whitepaper on gas shakingRotary gasshaker

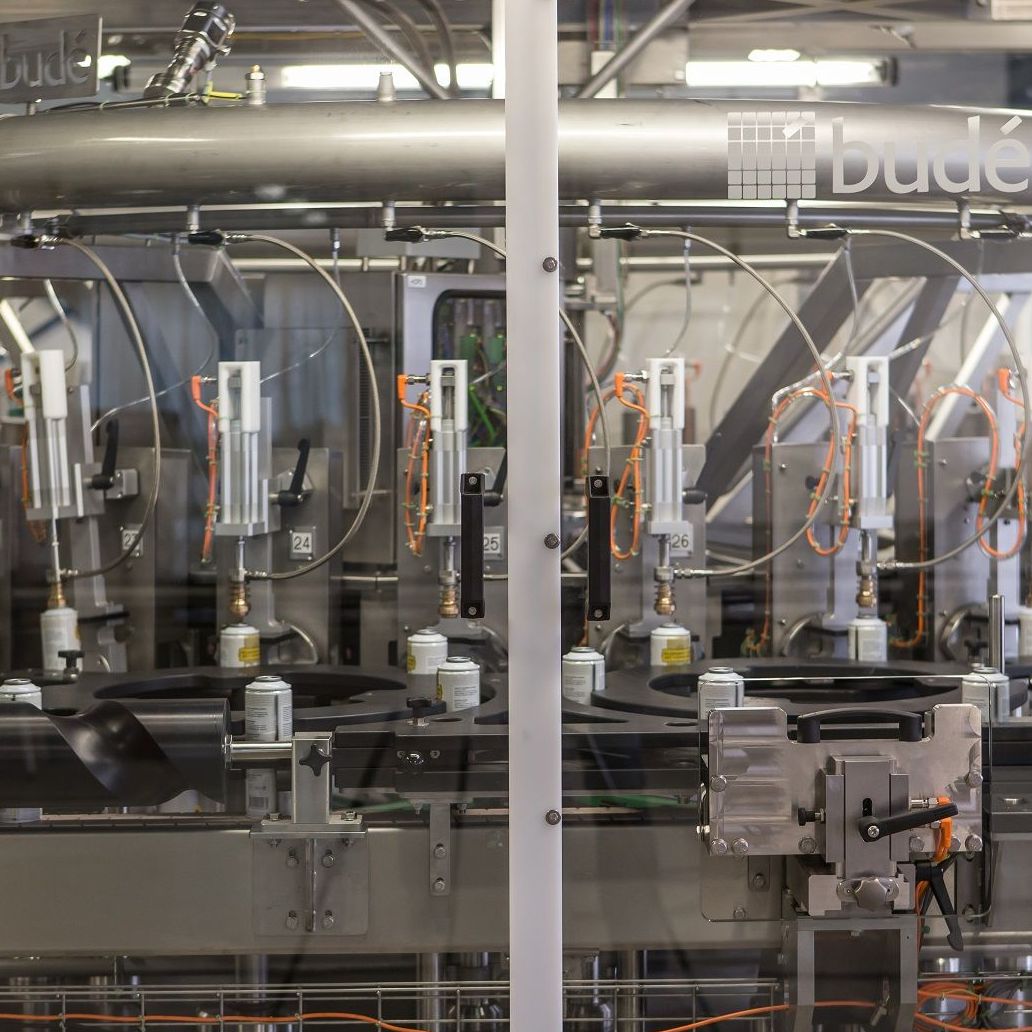

The Gasshaker technology was developed for the whipped cream industry, where machines need to be cleanable to ensure aseptic conditions during production. Over the years extra modules have been added, such as a can pressure tester, an automatic cleaning system, and a height detection system. Our portfolio includes rotary systems with a capacity ranging from 100 to 340 cans per minute.

The video below shows the rotary 60-piece gasshaker in action.

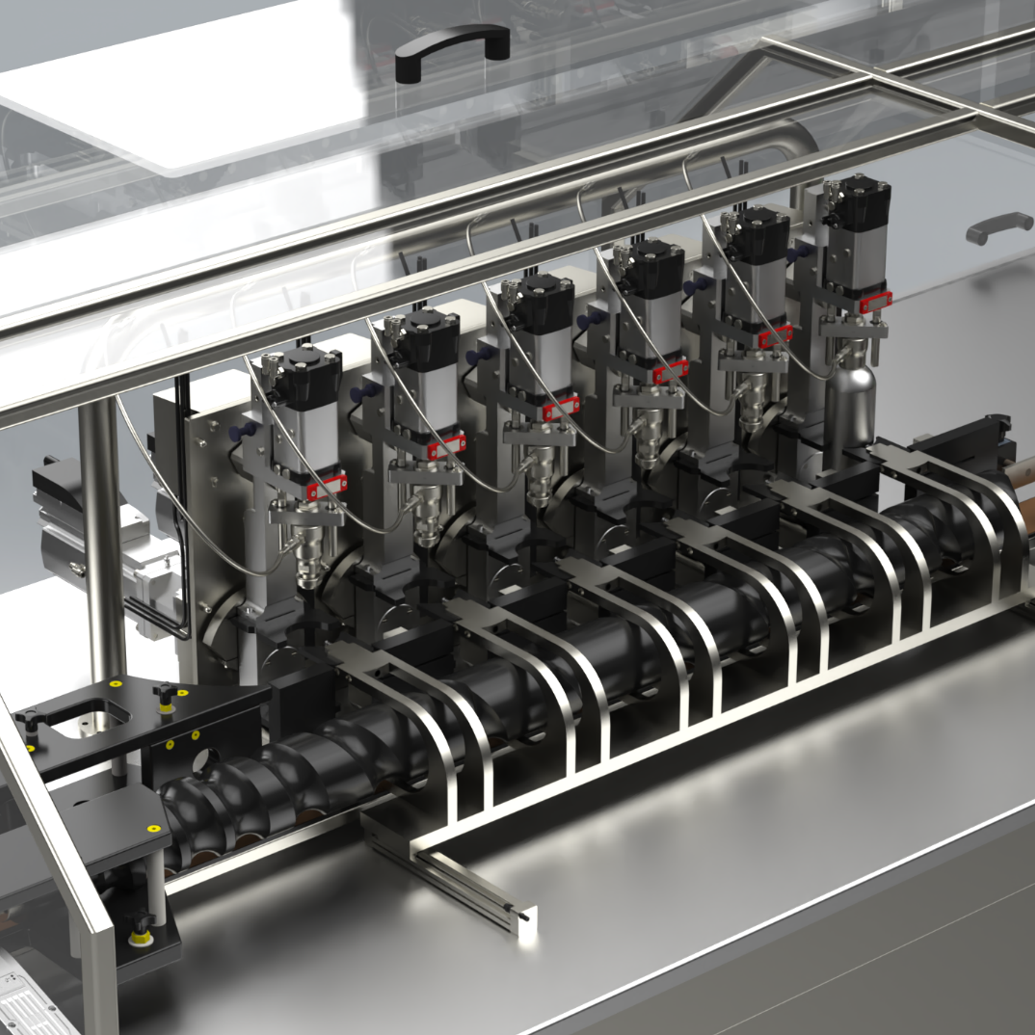

Linear gasshaker

Based on our proven gasshaking technology we designed the linear gasshaker for the regular aerosol market. The linear gasshaker is available in several versions that differ in size, ranging from 4 to 12 shake units. The speed of these linear systems varies between 10 – 60 cpm, depending on required the shake-times.

Contact us to discuss what makes sense for your situation.

download product sheet linear gasshaker

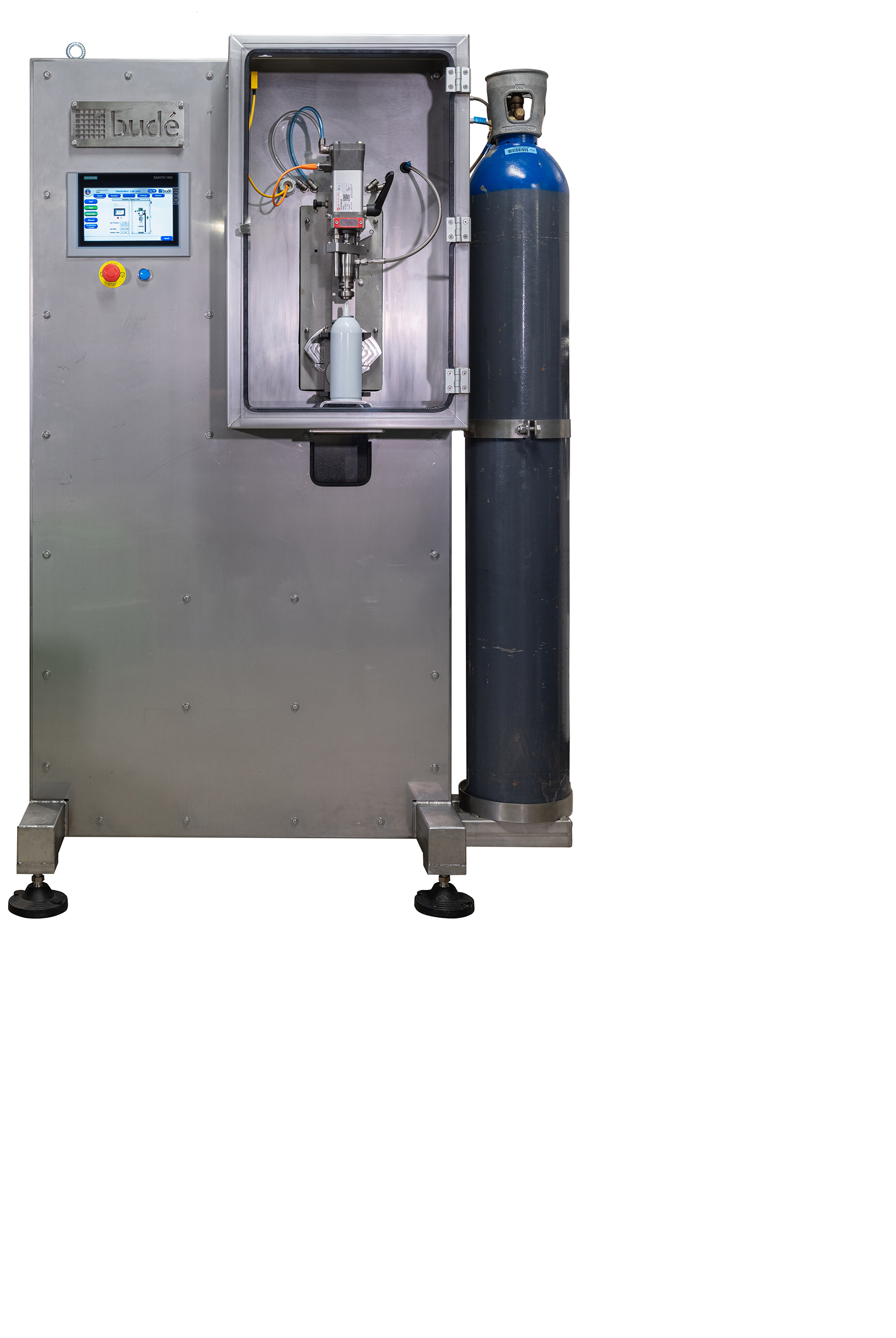

Semi-automatic gasshaker

The semi-automatic shaker unit is designed to offer the option to test concepts and configurations and to confirm if benefits can be achieved with the shaking technology. The unit comes with a simple touchscreen user interface. A crimping unit can be installed separately but could also be integrated next to the shaking unit. Different types of gas can be used while a mass-flow unit adds to the parameters that can be influenced and monitored. As such the unit is the ideal starting point to explore the opportunities that can be achieved with the shaking technology

download product sheet

"Some people are not aware of the technology"

Based on the discussions the company has had with aerosol manufacturers and fillers, there seem to be several things happening. Some people are not aware of the technology, as the way things are done is the way they have been done for many years. The fact that some conventional aerosols contain as low as 50% product and as high as 50% gas, is what companies understand and, as such, accept. This is especially the case for vapour gas products where this is needed to allow sufficient space for the propellant to expel all the product.

Contact