Testing

To ensure the finished product meets the requirements set, testing is essential. Statistical process control techniques using sampling at set intervals, are often used to ensure that only good quality product is sent to clients. Next to clients and quality requirements, there are regulations set by authorities that require testing to prevent dangerous situations where the requirement is that an aerosol needs to withstand a 50-degree Celsius temperature. New technologies allow in-line 100% testing for various potential quality and safety issues to stay in control of critical process parameters and eliminate rejects and complaints.

The advantages of in-line testing

The advantage of in-line testing is that 100% of the product is tested. Next to preventing poor quality product in the market, it eliminates the need for sampling and interval testing. It also allows to signal process variations based on which corrections can be made resulting in a more efficient production process.

Regulations require waterbath testing and the Budé inline pressure tester could eliminate this part of the process freeing up space and reducing cost significantly. If this is an option for your situation is something we are interested to discuss.

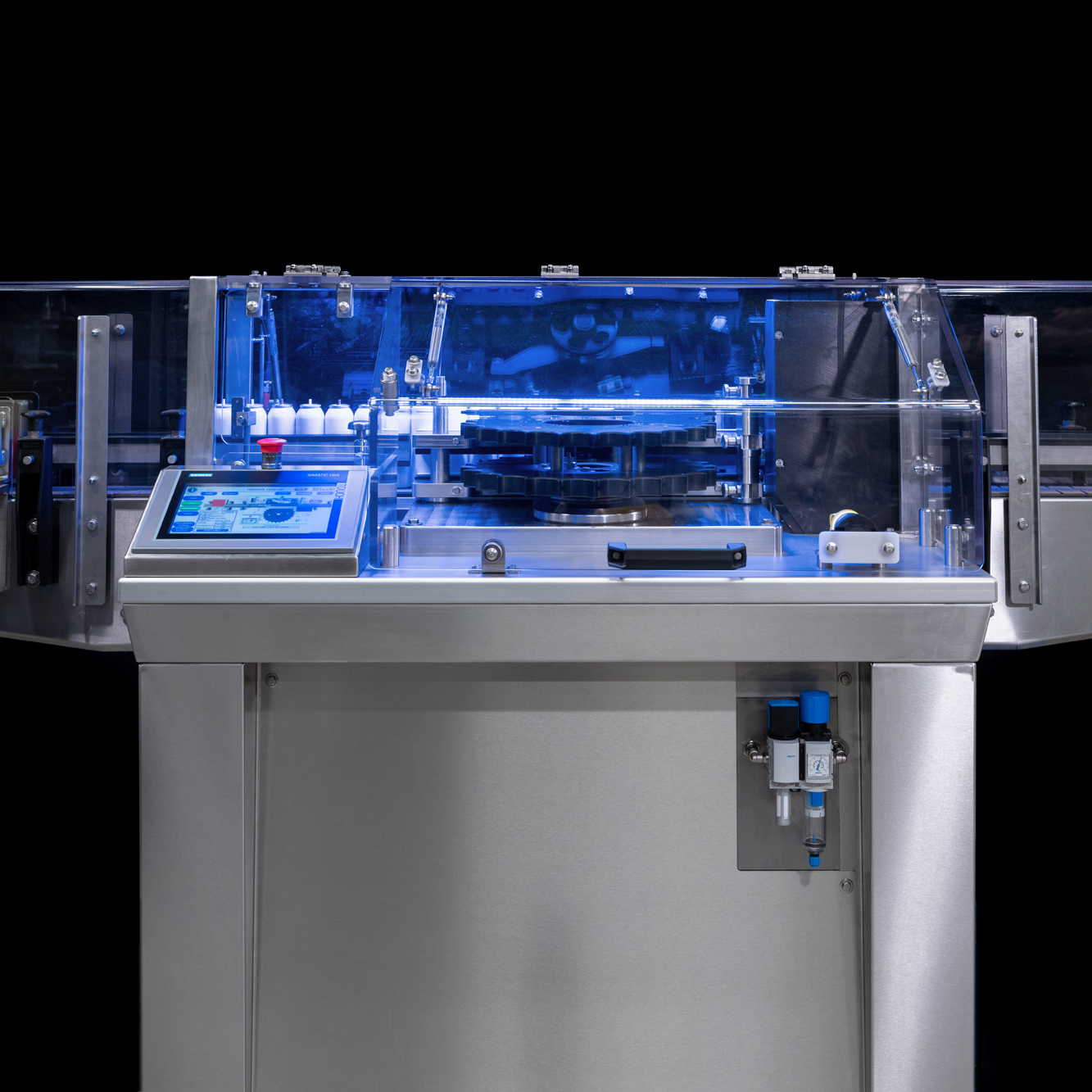

Testing Equipment

Budé offers a range of testing equipment for aerosol production lines:

- Can pressure, the pressure inside the can after filling

- Gas leakage, leakage of gas after filling due to poor crimp or valve malfunction

- Waterbath. traditional equipment for manual and inline use

- Other, we are always interested in exploring to design test equipment for other production critical parameters

Contact Budé to learn about its testing equipment

more on the Budé stand alone pressure tester