Gassing

Gassing refers to the process of inserting propellant gas in the can. The gassing method depends on the type of gas used, the construction of the aerosol, and the content. The main gassing methods we can offer are impact gassing, time over pressure, and under the cup. The Budé gassing shaking technology uses the “time over pressure” principle combined with a shaking (rotation) movement.

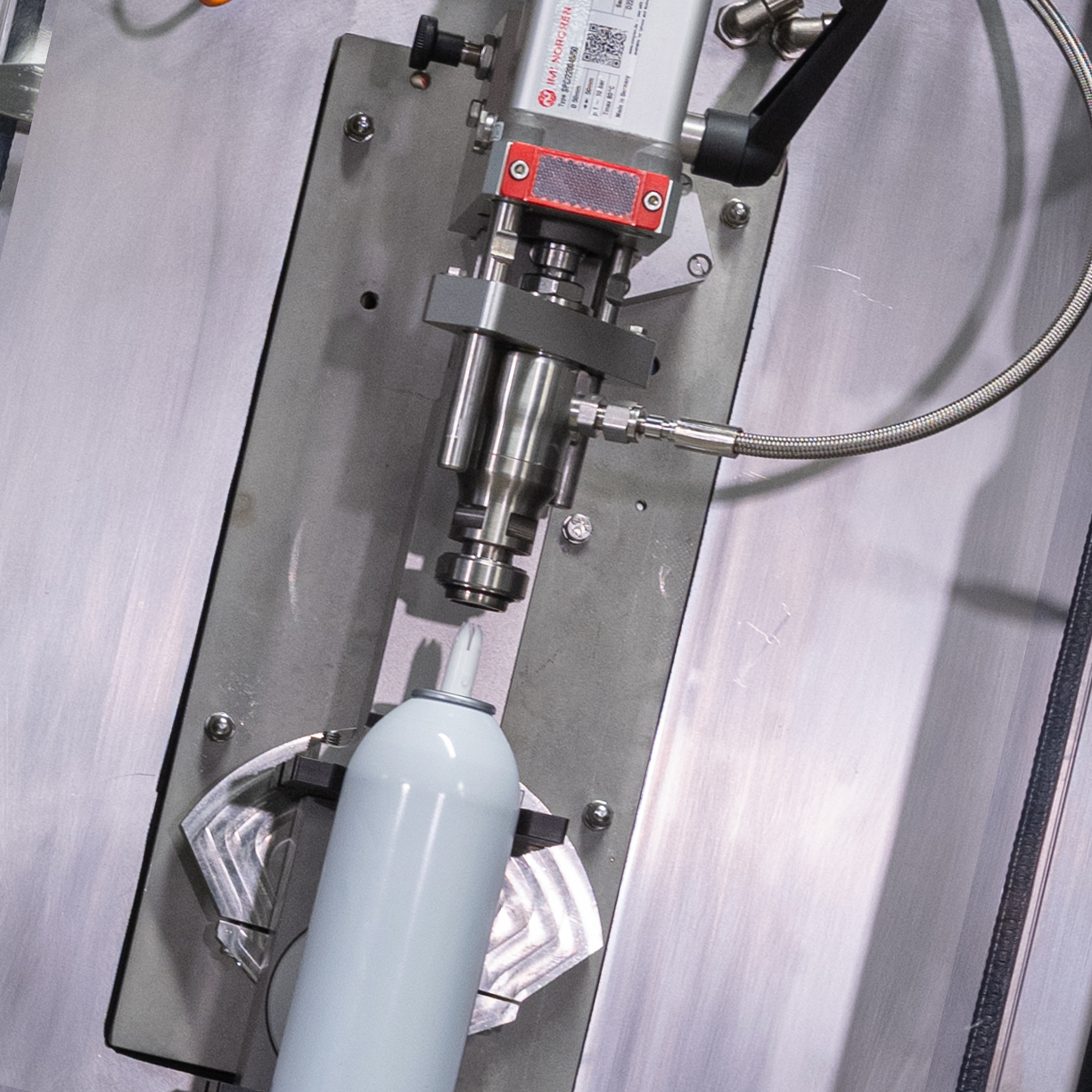

Gassing shaking

The Shaking technology is an improvement of the Time-Over-Pressure approach where during gassing the can is shaking allowing the propellant gas to be mixed with the content resulting in significantly higher amounts of gas when compared to regular TOP gassing.

Advantages:

- Increase can content

- No Atex propellants

- Alternative to BOV

Traditional gassing

The standard process of impact gassing is used with all thinkable flammable propellant gasses where the gas is added in liquid form. Impact gassing is also used in combination with CO2 and N2.

The alternative to impact gassing is the time-over-pressure technique where the gas just flows in the can until the pressure in the can reaches the pressure of the gas added.

More on Traditional gassing

BOV gassing

BOV packaging is simpler than traditional aerosol cans. Due to the bag, the content is not in contact with the propellant which is useful when filling product that is sensitive to certain gasses or that may react with the propellant such as food products, pharmaceuticals, and cosmetics.

more on BOV gassing

You can save up to 38 trucks per 100 trucks and 40% propellant a year by reducing the can diameter.

Rob Budé on gas-shaking

CEO Budé Group

Let’s get in touch

Let’s get in touch

Contact us